FOUNDRY (Shiroli)

- ARPA molding lines with PLC control

- Flask less size 508 X 508 X 200

- Flask Box size 711 X 635 X 250

- Producing Grey Cast Iron and ductile Iron casting

- 3D inspection of casting by GOM ATOS COMPACT SCAN 2M scanner, Germany

- Sand cooler from Sinpson (Control on Moisture and Temperature)

- Critical core setting using Pneumatic core setting fixtures

MACHINE SHOP

- Floor Shop Covering 34000 Sq. Feet

- Office Area Covering 6000 Sq. Feet

- Environment & Eco-Friendly

- Rain Water Harvesting System catering 35,000 liter/hour

- Robotic Pick & Place Line for mass production

- Well Equipped Metrology Lab with world class equipment, world class machine tools with combination of 2 Axis, 3 Axis, 4 Axis and latest 5 Axis Machines.

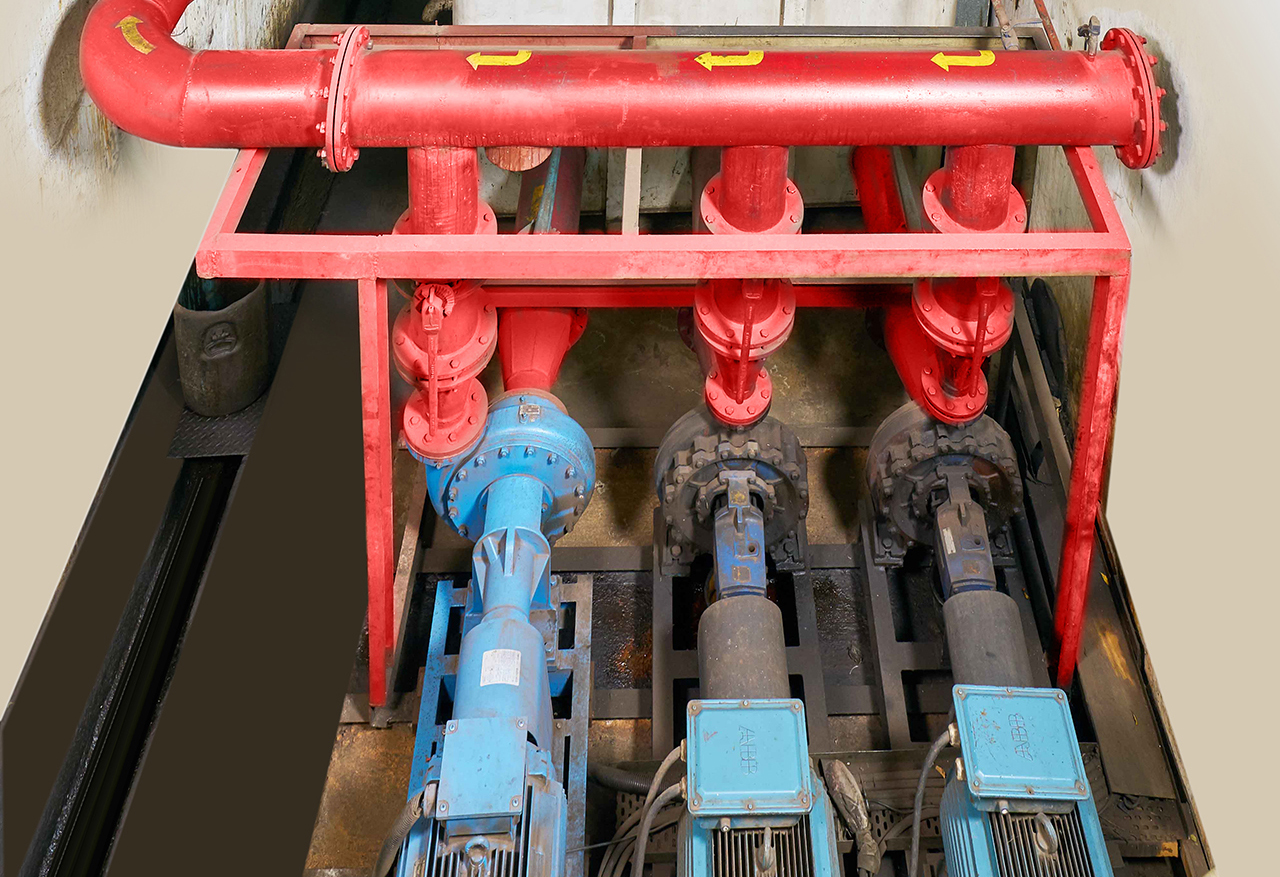

- Centralized Coolant System for effective coolant management.

FOUNDRY (Kagal)

- Installed 2000 MT/Month capacity of Grey Iron Casting.

- Commencement of Production from October 2020.

- High Pressure Flask less molding line from DISA.

- Flask Size: 610 x 710 x 254 (cope) + 254 (drag).

- Auto Pouring System.

- 3D inspection of casting by GOM ATOS COMPACT SCAN 2M scanner, Germany.

- Robotic fettling and core handling will be started in Second phase March 2021.

- Rain Water Harvesting System catering 100,000 Liters/Hour.

- Total Land : 3,74,000 Sq. Ft. (8.5 Acre).

- Built-up Area : 62,000 Sq. Ft.